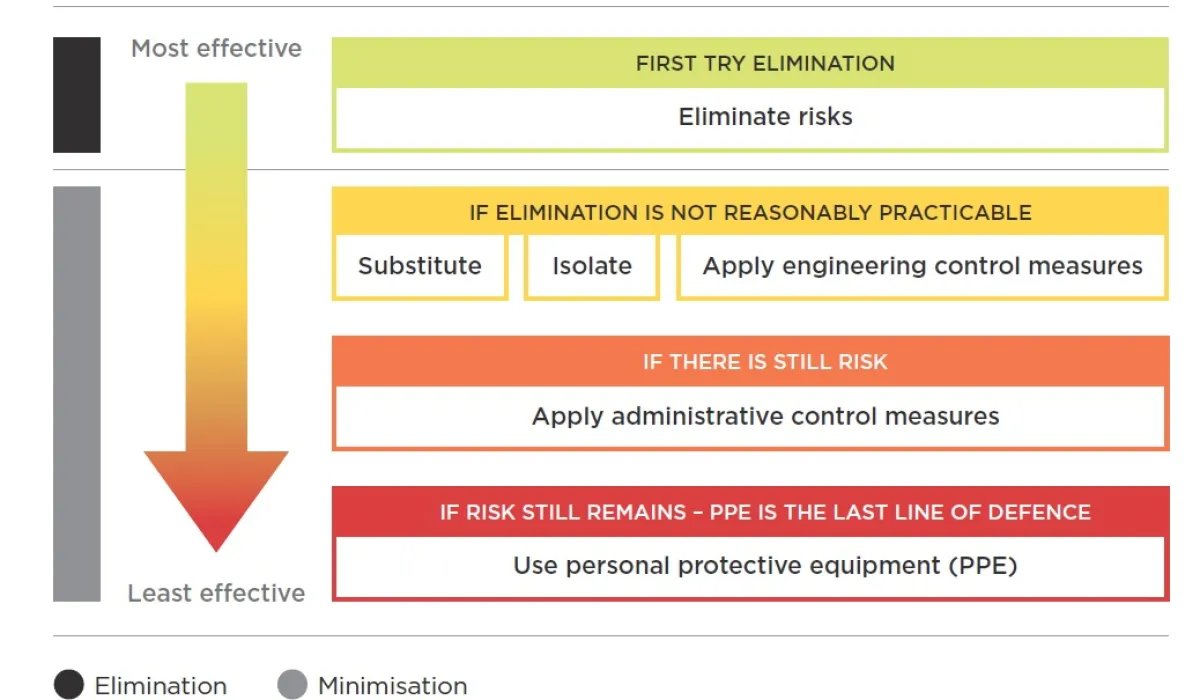

Businesses must manage the health and safety risks from silica dust at work by using the hierarchy of control measures. This ranks control measures from the highest level of protection to the lowest.

Processing crystalline silica

Any activity that has the potential to generate and expose workers or others at the workplace to respirable crystalline silica (RCS) is considered ‘processing’ of a crystalline silica material.

At least one of the following isolation or engineering control measures must be used during processing of a material containing crystalline silica:

- isolate a person from silica dust exposure

- fit a fully enclosed operator cabin with a high efficiency air filtration system

- use an effective wet dust suppression method

- use an effective on-tool extraction system

- use an effective local exhaust ventilation system

If a worker is still at risk of being exposed to silica dust after the measures above are implemented or are not possible, then they must be provided with the right respiratory protective equipment and ensure it is worn while doing the work.

Hierarchy of control

Under work health and safety laws, a PCBU must use the hierarchy of control measures to eliminate or minimise risks for all hazardous chemicals, including RCS. The hierarchy of control measures ranks control measures from the highest level of protection and reliability to the lowest level. Working through the hierarchy of control from the top to bottom helps determine the most effective methods to manage the risks.

Elimination

Elimination is the most effective control and must always be considered before all other control measures. Eliminating crystalline silica may not always be reasonably practicable.

Substitution

Substitution is the replacement a product or process with something that is less hazardous and therefore has a lower risk. For example:

- use products containing less crystalline silica

- use a crystalline silica material that does not need to be processed

- scoring and snapping tiles instead of cutting them with a power tool.

Substitution may not be practical where crystalline silica is naturally occurring or if it means you cannot make the required product or deliver a required service.

Isolation

Isolation involves physically separating the source of harm from people, for example:

- isolating high dust generation work in an enclosed room with restricted access

- providing physical barriers and exclusion zones between different workers and workstations.

For isolation to be effective the processing should take place within a fully contained system. Different industries have specific guidelines for their unique situations regarding isolation.

Where exclusion zones are set up, warning signs should be placed so that they are clearly visible before entering the area. Signs should warn that:

- there is a silica dust hazard present

- access to the area is restricted to authorised persons

- RPE should be worn in the exclusion zone.

Engineering controls

Engineering controls use physical methods, mechanical devices or processes that eliminate or minimise exposure of workers to RCS, for example:

- general ventilation

- local exhaust ventilation

- using wet processing methods

- drills, routers, saws and other equipment fitted with dust extractors and/or a water attachment to suppress dust

- cleaning up dust with an M- or H-class industrial vacuum cleaner.

Engineering controls alone are not sufficient to ensure the processing of crystalline silica is controlled.

RCS is abrasive and can cause damage and wear to tools and equipment that are part of engineering controls. Regularly inspect equipment for:

- wear and tear, corrosion or damaged parts

- air leaks in pneumatic tools

- kinks, holes or leaks in water suppression or dust extraction equipment,

- damage to guards and flaps that contain water spray.

Administrative controls

Administrative controls rely on worker behaviour to be effective, so it is very important that policies and training are also in place. To ensure compliance, appropriate supervision is needed. Examples of administrative controls for RCS include:

- planning cutting tasks to ensure the minimum number of cuts

- written rules and policies for working with crystalline silica

- a maintenance schedule and log for equipment and personal protective equipment

- limiting the length of time a worker may be exposed to RCS.

Personal protective equipment

Personal protective equipment (PPE) does not prevent dust creation and therefore cannot be relied on solely as protection from RCS. However, it can be effective at minimising residual risk after other control measures have been implemented.

Respiratory protective equipment (RPE) is PPE that is designed to protect the wearer from inhaling airborne contaminants. RPE must be properly fitted to the wearer and maintained.

Further information

Safe Work Australia:

Workplace exposure standards/limits

PCBUs must ensure that workers are not exposed to RCS dust at the workplace at a level above the exposure standard.

The exposure standard for airborne respirable crystalline silica is 0.05mg/m3 as an eight-hour time weighted average (TWA).

The TWA refers to the average airborne concentration of a substance when calculated over an 8-hour working day, for a 5-day working week.

Where a workplace has working hours that exceed an 8-hour day or a 40-hour week, the TWA needs to be adjusted to compensate for the greater exposure.

TWA exposure standards must not be adjusted (increased) for shorter work shifts.

WHS regulators may put additional limitations on exposure. Information on regulators in your jurisdiction and how to contact them can be found on our WHS Regulators page

Further information

Safe Work Australia: Airborne contaminants - Workplace exposure standards/limits | Safe Work Australia

Air monitoring

Air monitoring for crystalline silica involves sampling the air for respirable crystalline silica within the employees’ breathing zone.

Employers must carry out air monitoring if their employees could be exposed to levels of silica dust that are above the exposure standard. Air monitoring must also be carried out:

- when there are changes to work practices

- if a health monitoring report for an employee indicates that they might be experiencing health issues related to silica exposure

- if a health and safety representative has a suspicion based on reasonable grounds that the exposure level may be exceeded.

The interpretation of these results, including comparison with the exposure standard, should be carried out by a competent person, such as an occupational hygienist.

Further information

Australian Institute of Occupational Hygienists: What do I need to know about air monitoring?

Health monitoring

Health monitoring must be provided if exposure to crystalline silica is reasonably likely to have an adverse effect on a worker’s health.

Health monitoring must be done under the supervision of a registered medical practitioner and should be carried out by a specialist occupational or respiratory physician.

The National Occupational Respiratory Disease Registry (NORDR) stores data on occupational respiratory diseases in Australia. For all states and territories, it is mandatory for physicians to report cases of silicosis to NORDR. Other silica-related diseases can be reported to NORDR with patient consent.